Upstream Risk Management

COMPLIANCE SUPPORT

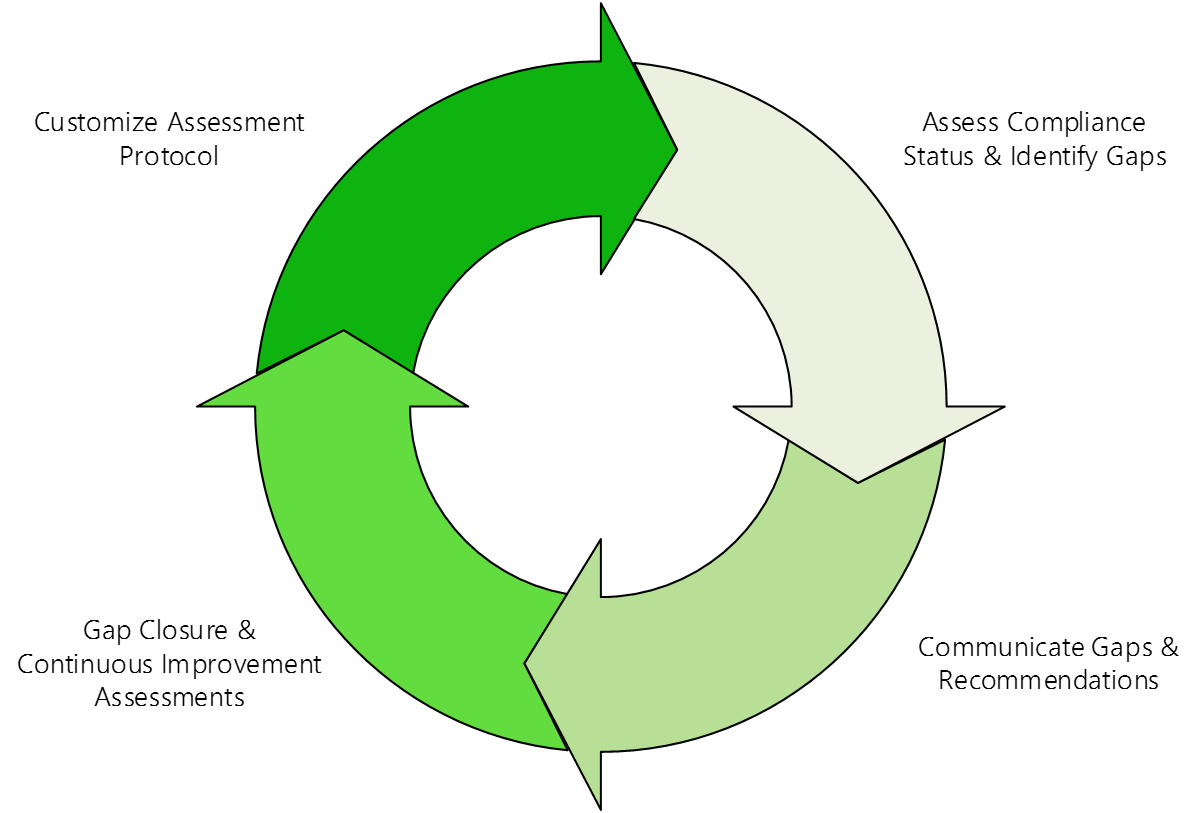

In alignment with existing government and industry regulations, and as new and more stringent standards are approved, Energy Risk Consulting can provide support to assess compliance status with requirements, and to develop and implement strategies to close identified gaps.

ERC can support organizations to achieve comprehensive compliance with:

Government Regulations and Requirements

Industry Standards and Requirements (API, ISO, etc.)

Internal Company Policies and Governance

Process

Comprehensive and Detailed: Our assessment process is directly aligned with the applicable regulations and standards and provides for a thorough evaluation and understanding of compliance status.

Organized and Repeatable: A structured project execution approach is applied for each assessment to ensure clear alignment on expectations and complete documentation of the process and results.

Collaborative: ERC works closely and collaboratively with clients to define assessment needs and customize the implementation approach to achieve customer objectives.

Risk Analysis

With global experience conducting risk analyses on an extensive number of technical systems for a variety of customers, Energy Risk Consulting is committed to supporting clients in minimizing risks to safety, the environment, and operations. Our ability to utilize a wide variety of risk analysis methodologies (including HAZID, HAZOP, LOPA, FMECA, etc.), coupled with our streamlined work process, allows us to develop unique solutions for each customer which maximize value while minimizing cost and session duration.

Benefits

Identification of critical risks with potential for safety, environmental, and business impacts

Increased understanding of systems and interfaces via system overview discussions and detailed analyses

Development of recommendations (including SIT) to mitigate risks, increase system reliability and safety, and decrease downtime

System Experience

ERC and its employees have conducted numerous technical risk assessments on a variety of systems including:

Active Heave Drawworks (AHD)

Anti-Collision

Auxiliary Winch

Bilge and Ballast

BOP Control

BOP Handling

Braking Resistors

Bulk System

Choke & Kill Manifold

Charge Pumps

Control System Logic

Cooling Water System

Cyberbase

Diverter

Driller’s Control Cabin

Drilling Controls Network

Drilling Drives

Drill Floor Integration

Drilling Power Limiting Systems (DPLS)

Emergency Evacuation

Emergency STOP (drill floor machines)

Fire and Gas Detection

Fire Fighting

HP Mud Pumps

HP Cement Pumps

Iron Roughneck

Knuckle Boom Cranes

Lube Oil Cooling

Main Pumps

Mooring System

Mud Control System

Mud Pump System

Mud Mixing and Solid Controls

Pipe Handling Catwalk Machine

Pipe Handling Crane (9 ton)

Pipe Handling

Pipe Racking

Power Management

Rig Cooling

Ring Line HPU

Riser Handling

Riser Tensioning

Thrusters

Top Drive

Variable Speed Drive

Variable Frequency Drives (Drilling)

Water Tight Integrity

Well Control

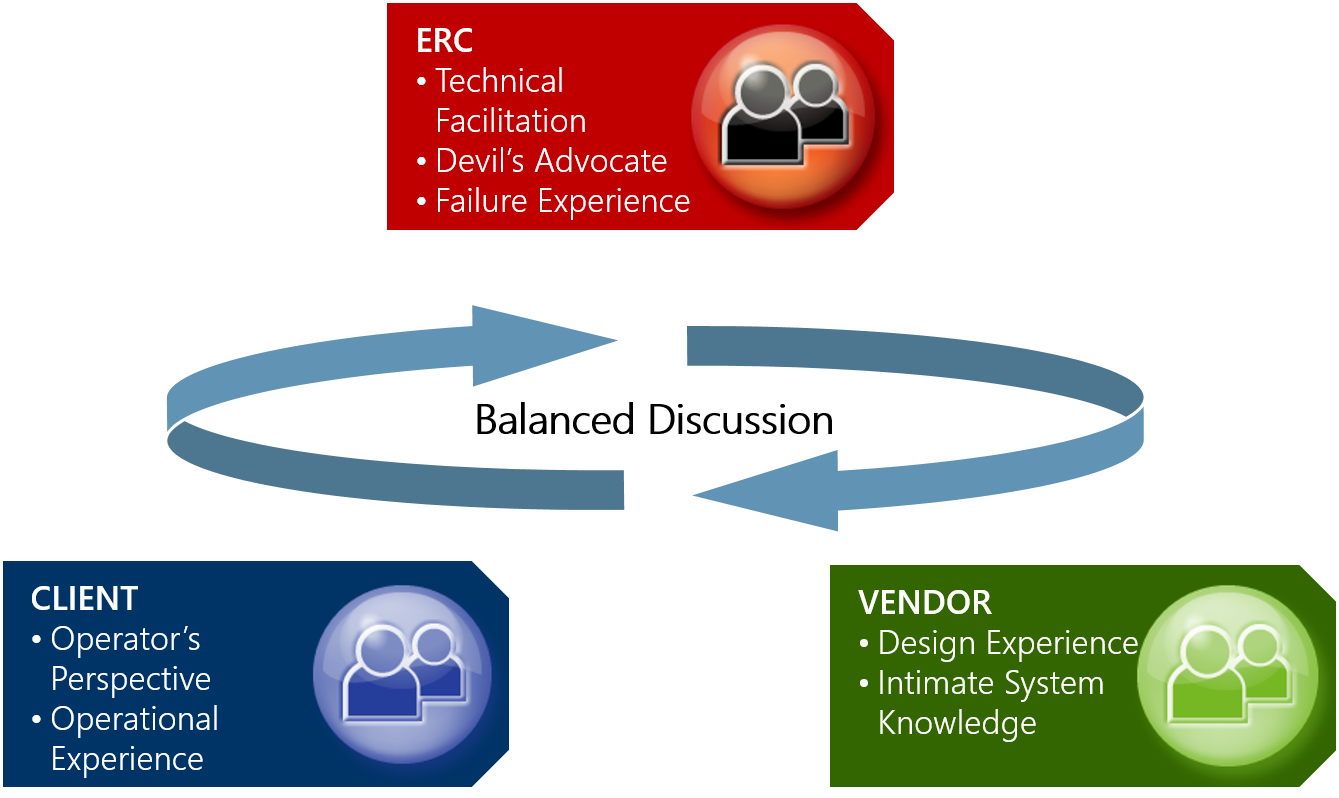

Methodology

Energy Risk Consulting is focused on maximizing value and productivity during hazards analysis sessions/meetings. The standard approach for conducting these meetings is to begin each review with blank documentation and utilize a brainstorming approach coupled with the selected methodology (HAZID, HAZOP, FMEA/FMECA, etc.) to identify scenarios and populate the associated worksheets. Although our experienced staff are fully capable of using this approach, in the interest of maximizing the value of the review sessions where a number of participants from the customer (project, engineering, and operations staff) and vendor(s) may be involved, alternative strategies may be used.

With a risk management staff consisting of experienced engineers, Energy Risk Consulting is capable of reviewing technical system documentation (Electrical Diagrams, Hydraulic System Diagrams, P&IDs, etc.) to develop preliminary system failure scenarios (failure causes and modes only – consequences and risk ranking are always recommended to be completed during sessions). In addition, our recommended approach involves scheduling a brief preliminary meeting, or preparation session, with a small group of engineering staff knowledgeable of the system design. The intent of this preparation session is to:

Verify the scope of the suggested study nodes

Verify the accuracy of preliminary system failure scenarios

Establish and build relationships with the meeting participants which increases productivity during the full hazards analysis sessions

Using this work process to prepare for and execute hazards analysis meetings increases session productivity and value in the following ways:

Minimizes session duration – preliminary preparation by Energy Risk Consulting engineering professionals coupled with the preparation session with the small group of design engineers allows for the majority of failure scenarios to be identified and pre-populated into worksheets prior to starting the formal hazards analysis meetings. This preparation work, therefore, eliminates the time that would have been spent developing and documenting these scenarios during a formal session with the full group of participants, significantly reducing both the session duration and cost.

Allows participants to focus creative brainstorming on identifying less obvious system failures – an additional benefit of preparing failure scenarios and documentation prior to the hazards analysis sessions is that participants are then able to focus discussions on the consequences and risks of the identified failures, and on creative brainstorming of additional failure scenarios that are less obvious, such as those that are based on operational experience.

Session Approach